Company profile

| Company name | NFT CO., LTD |

|---|---|

| Representative | Representative Director Hiroshi Hamada |

| Address | 〒818-0131 Mizuki 1-11-11 of Dazaifu City, Fukuoka Prefecture |

| TEL | +8192-921-1525 |

| FAX | 092-921-1441 |

| Established | August 1986 |

| Capital | 40 million yen |

| Number of employee | 96名 (グループ全体 247名)※2024年10月現在 |

| Business contents | Design, manufacture and sale of semiconductor encapsulation molds, semiconductor manufacturing equipment, related parts and peripheral units |

| Related company | 11 countries (Mainly Japan, Southeast and East Asia), 320 companies |

| URL | https://www.nft-g.co.jp/ |

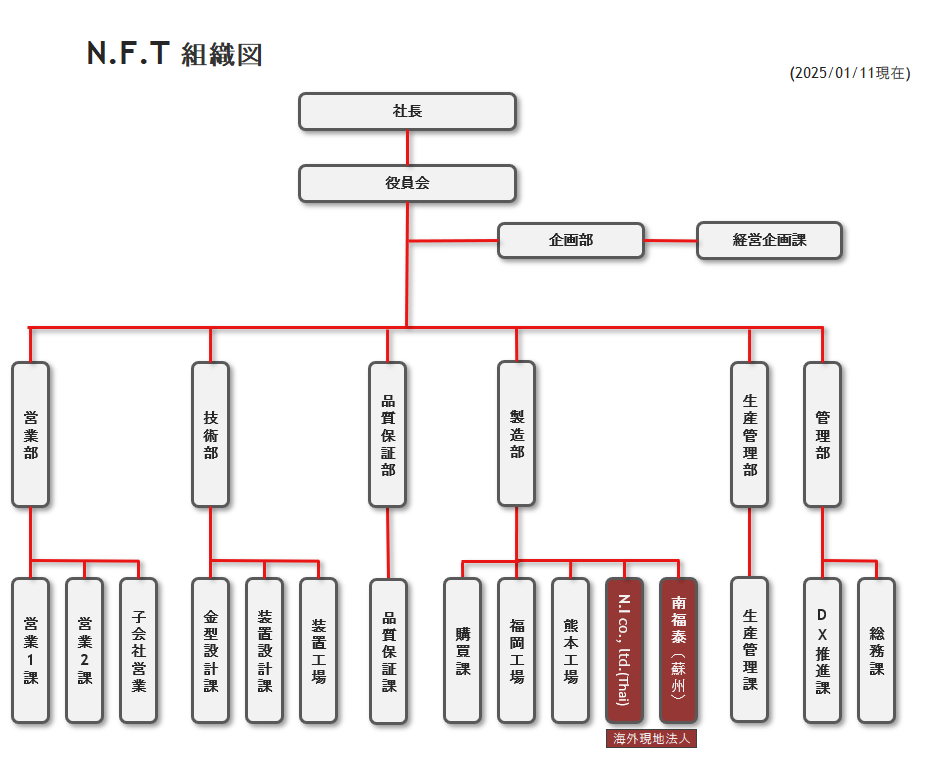

N.F.T 組織図(2025/01/11現在)

History

- 1985.08 N.F.T Company was established in Mizusuki 1-23-36, Dazaifu City,

- 1988.08 Increased capital to 10 million yen

- 1989.06 Relocation for Head office and factory to Mizuki 1-10-11 of Dazaifu City, Fukuoka Prefecture

- 1991.07 Kumamoto factory in Kumamoto prefecture Tamana-gun Namguoku-machi becomes operational

- 1991.08 Increased capital to 20 million yen

- 1994.07 Expansion and enhancement of the Kumamoto factory

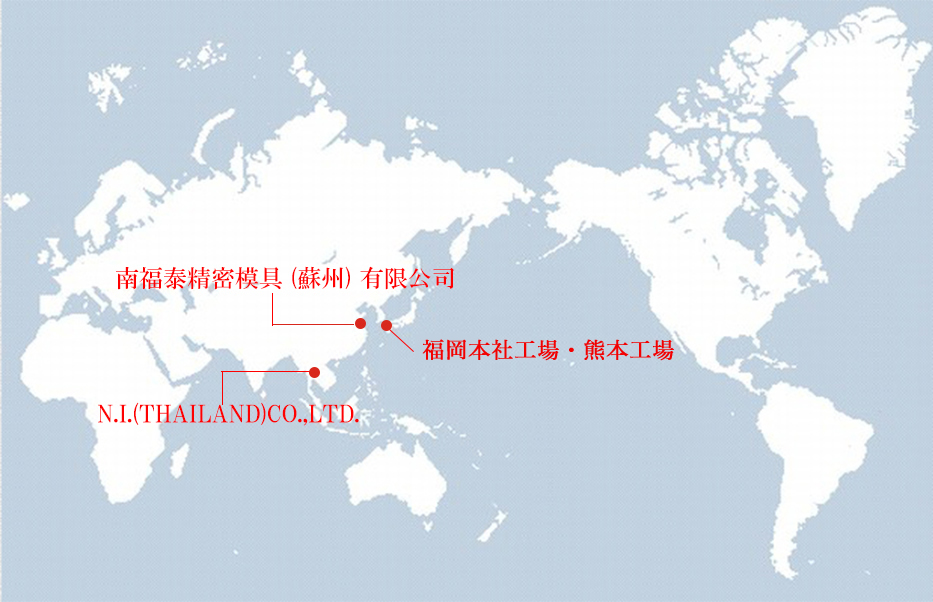

- 1995 (H07) July Established overseas subsidiary NI (THAILAND) CO., LTD. In Ayutthaya Province, Kingdom of Thailand

- 2000.08 Increased capital to 40 million yen

- 2001.03 Plating factory inside Kumamoto factory was constructed

- 2001.05 Expansion and enhancement of N.I.(THAILAND)CO.,LTD. factory

- 2002.06 Establishment of Minami Fu-Tai Precision Molding Equipment (Suzhou) Co., Ltd. in Suzhou City, China

- 2003年 (H15) 7月 ISO9001認証取得(N.I)

- 2004.01 System business was started

- 2005年 (H17) 6月 ISO14001認証取得(本社)

- 2010年 (H22) 6月 ISO9001認証取得(蘇州)

- 2010.08 System business facility assembly factory was moved near Fukuoka head office

- 2016.12 N.I. (THAILAND) CO., LTD. New factory completed, relocated

- 2017年 (H29) 6月 ISO9001認証取得(熊本工場)

- 2021年 (R03) 7月 JISQ9100認証取得(本社&熊本工場)

Company base・Location

| 本社/福岡工場/装置工場 Tel : 092-921-1525  | 〒818-0131 Mizuki 1-11-11 of Dazaifu City, Fukuoka Prefecture |

|---|---|

| 熊本工場 Tel : 092-921-1314  | 〒861-0814 764-1 Namguoku-machi of Tamana-gun, Kumamoto prefecture |

Related company

Equipments owned

| processing details / purpose | Equipment name | number of equipment | processing range |

|---|---|---|---|

| grinding groove Cut | Forming surface grinder | 42 | 300 x 150 x 200 |

| Surface grinder | 8 | 600 x 400 x 300 | |

| CNC Forming surface grinder | 8 | 300 x 150 x 200 | |

| CNC jig grinder | 4 | 1300 x 650 x 300 | |

| Equipment grinder | 6 | φ 2.0 to φ 12.0 | |

| Milling processing | High speed machining center | 5 | 400 x 350 x 300 |

| Machining center | 5 | 600 x 450 x 350 | |

| NC milling machine | 4 | 500 x 300 x 300 | |

| Milling machine | 6 | 450 x 250 x 300 | |

| Milling Electrode processing | NC Electrode processing | 9 | 320 x 280 x 300 |

| EDM | NC EDM processing machine | 24 | 400 x 300 x 250 |

| Square hole | WC EDM machine | 9 | 400 x 300 x 150 |

| Pinhole | NC processing machine | 4 | 300 x 200 x 300 |

| Plating Matt finish Surface treatment | Plating machine | 3 | 400 x 400 x 100 |

| Peening machine (cleaning, peening) | 2 | 200 x 200 | |

| Cylinder | Lathe | 2 | φ 100 x 200 |

| Hole | Drill machine | 4 | φ13 × 100 |

| Upright drilling machine | 3 | φ30 × 300 | |

| Cut | Sawing machine | 4 | 500 x 250 x 200 |

| Engraving | Laser graving machine | 1 | 200 x 90 x 100 |

| General graving machine | 1 | 300 x 150 x 30 | |

| Burr remover | Milling machine(plastic、glass beads) | 7 | – |

| Measurement・check | CNC surface quality measuring machine | 1 | 200 x 200 x 200 |

|---|---|---|---|

| Surface roughness calculato | 4 | X = 50 mm | |

| Profile projector | 8 | 100 x 40 x 80 | |

| 3D measuring machine | 1 | 400 x 400 x 300 | |

| Hardness checking machine | 1 | – | |

| Factory microscope | 22 | 200 x 100 x 150 | |

| Image measuring machine (3D measuring function attached) | 1 | 400 x 400 x 200 | |

| Digital measuring machine | 37 | Z = 250 mm | |

| Check mold (testing mold) | transfer mold machine | 5 | 200 t, 125 t, 100 t, 80 t |

| CAM | 2D-CAM | 5 | – |

| 3D-CAM | 5 | – | |

| 3D-CAD | 3 | – | |

| Design | 2D-CAD | 23 | – |

| 3D-CAD | 12 | – | |

| Compound flow analysis software | – | compound floating / filling path Hardening time / contraction and warpage | |

| Structure analysis software | – | stress/ Thermal stress Heat conduction / Natural Frequency |

ISO14001

Considering environmental issues, every company faced increased demands for social responsibility as possible as they could.

Currently, surroundings on earth have been deteriorated by environmental problems such as Global warming, extraordinary weather, air pollution, marine pollution, soil contamination…etc. In addition, social responsibility itself becomes heavier than ever, because of many pollution-related diseases. We established highly advanced civilization but at the same time, we now confront with lost in abundant nature. The earth, we live right now, is not eternal place.

We should recover and preserve uncontaminated nature to inherit this treasure which is named earth to the next generations. It is our responsibility.

We are also making effort for preserving nature, in spite of our poor condition. With introduction of environmental management system based on ISO 14001, we made a progress on environmental improvement of our overall business activity.

Basic idea

We, NFT are aware of global environmental problem is the first priority to mankind. As for marketing and manufacture of encapsulation of semiconductor and facilities and related parts, every staff carrys out environmental management, according to NFT’s environmental policy as we stated below.

Environmental Policy

- We are making an effort to forestall contamination and carry out resource saving and waste reduction at the same time.

- We are strictly observing agreements with business partners and neighbors and following ordinance and regulations by law.

- We are constantly implementing improvement and maintenance on environmental management system by appropriate operation.

- We are carrying out environmental management with periodical improvements in order to fulfill environmental purpose and objects we established

- We are making progress on promotion activity including education with thorough understanding of this environmental policy

- We are declaring our environmental policy including basic idea toward outside of company

Quality policy

Our basis for everyday task is 『Stability on Quality

We could provide best semiconductor process with our special engineers by cooperating and brainstorming with clients.

- We devote to eliminate uneven product quality and to achieve「Stability on product quality」, based on dimensional tolerance.

- We devote to reduce internal failure and check progress to achieve 「observation for delivery day」based on process management.

- We devote to achieve「mass production and small quantity batch production」 based on flexible production plan and multi skilled engineers

Quality targets

According to our quality policy, we decide targets as stated below

- No user claims

According to our quality policy, we decide targets as stated below. - Reduction of defect rate

We establish a system that could reduce defect rate, by investigating reason for defects, - Maximum output by process management.

With flexible working system and development of human resource, we aim to train multi-skilled engineers

Membership of professional institutions

九州半導体・エレクトロニクスイノベーション協議会(SIIQ)

福岡県半導体・デジタル産業振興会議

九州航空宇宙開発推進協議会

九航協エアロスペース・ネットワーク(QAN)

福岡県航空機産業振興会議

福岡県航空機産業研究会(FAIN)

九州ヘルスケア産業推進協議会(HAMIQ)

ふくおか医療福祉関連機器開発・実証ネットワーク

福岡県ものづくり中小企業推進会議

(熊本県)南関町金型金属加工企業連絡協議会

大分県LSIクラスター形成推進会議