開発・設計

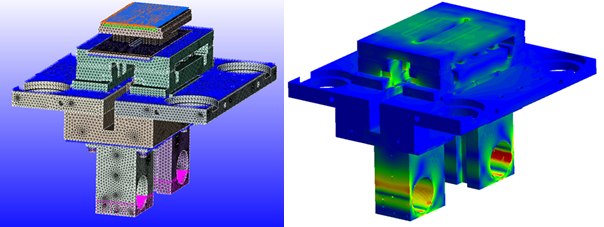

金型設計

半導体パッケージング用金型のことなら弊社に一度お声掛け下さい。 20年前から自社設計して蓄積してきた技術を基に新規設計、既存金型の改善提案、試作型設計などを行っています。パーツ/型を預かってのリバースエンジニアリングも対応しています。お客様にとってベストな半導体プロセスを提供します。

半導体パッケージング用金型のことなら弊社に一度お声掛け下さい。 20年前から自社設計して蓄積してきた技術を基に新規設計、既存金型の改善提案、試作型設計などを行っています。パーツ/型を預かってのリバースエンジニアリングも対応しています。お客様にとってベストな半導体プロセスを提供します。

装置設計

トランスファモールド装置の設計及び製作を行っております。 大量生産、多品種少量生産等、用途に応じたラインナップを用意しております。また、あらゆる特殊仕様への対応が可能なため、お客様が本当に必要としているものを製作させていただきます。

トランスファモールド装置の設計及び製作を行っております。 大量生産、多品種少量生産等、用途に応じたラインナップを用意しております。また、あらゆる特殊仕様への対応が可能なため、お客様が本当に必要としているものを製作させていただきます。

開発

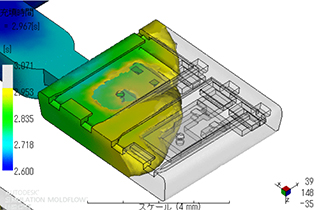

創業以来、多種多様な業種で培って来た開発技術ツールを活用し、お客様の御要求に対応した最新技術を提供します。

創業以来、多種多様な業種で培って来た開発技術ツールを活用し、お客様の御要求に対応した最新技術を提供します。

お客様の問題点を共に考え解決策を見出します。

精密金属加工

研削加工

半導体用金型全般の製作加工が可能で、近年はセンサー関連のレンズ形状等も社内製作にて取組んでおり、実績もあります。

半導体用金型全般の製作加工が可能で、近年はセンサー関連のレンズ形状等も社内製作にて取組んでおり、実績もあります。

お客様の御要望に応じたパーツ製作対応を行っております。

フライス加工

樹脂材料から超高硬度金属・セラミックまで加工が出来、プレート加工から高精度微細加工・3D形状加工までリニアのマシニングで幅広く対応いたします。

樹脂材料から超高硬度金属・セラミックまで加工が出来、プレート加工から高精度微細加工・3D形状加工までリニアのマシニングで幅広く対応いたします。

放電加工

近年、製品の高精度化、複雑化に伴い放電加工に求められる役割も大きくなっております。弊社では放電加工機をメインとして10台を使用しIC PKG、レンズ形状、超微細加工まで幅広く手掛けておりますのでお客様のニーズに応じた対応が可能です。

近年、製品の高精度化、複雑化に伴い放電加工に求められる役割も大きくなっております。弊社では放電加工機をメインとして10台を使用しIC PKG、レンズ形状、超微細加工まで幅広く手掛けておりますのでお客様のニーズに応じた対応が可能です。

仕上げ/磨き

複雑形状キャビティや、光学系レンズ等の磨きを熟練の技術により行っております。また離型性向上のためのマイクロブラストによる梨地付け、処理前のガラスビーズによるバリ取り、洗浄等も対応いたします。

複雑形状キャビティや、光学系レンズ等の磨きを熟練の技術により行っております。また離型性向上のためのマイクロブラストによる梨地付け、処理前のガラスビーズによるバリ取り、洗浄等も対応いたします。

表面処理

表面処理は下地処理が大切です。

表面処理は下地処理が大切です。

NFT独自のノウハウによる下地処理と機能的なメッキ選択により、お客様の要求を越える表面処理を提供いたします。

組立・試圧

金型組立/試圧

自社製作金型は社内組立、試圧までを一貫して行い、お客様の生産に即起用して頂ける様に製作から生産開始までのトータルサポートを行っております。 お客様の御要望に応じて、金型の診断、問題解決の改造などニーズに応じた対応を行っております。

自社製作金型は社内組立、試圧までを一貫して行い、お客様の生産に即起用して頂ける様に製作から生産開始までのトータルサポートを行っております。 お客様の御要望に応じて、金型の診断、問題解決の改造などニーズに応じた対応を行っております。

装置組立

装置の提案から組立、調整、点検、据付、アフターフォローまで一括対応いたします。 海外でもエンジニアによる操作方法からメンテナンス方法、トラブルシューティングまでトレーニングをさせていただき、導入初期から安定した生産へ貢献いたします。お困りのときは、お電話一本でエンジニアによる丁寧な対応をいたします。

装置の提案から組立、調整、点検、据付、アフターフォローまで一括対応いたします。 海外でもエンジニアによる操作方法からメンテナンス方法、トラブルシューティングまでトレーニングをさせていただき、導入初期から安定した生産へ貢献いたします。お困りのときは、お電話一本でエンジニアによる丁寧な対応をいたします。

アフターフォロー・メンテナンス

アフターフォロー

社内試作後、実機での調整を含め、最終の製品確認まで、責任を持ってご対応させて頂きます。

社内試作後、実機での調整を含め、最終の製品確認まで、責任を持ってご対応させて頂きます。

問題発生の際は、弊社エンジニアが直接お客様の工場にお伺いさせて頂き、問題を解決致します。

メンテナンス

金型・装置共にメンテナンスを実施する事により、より良く長期に渡ってご使用していただけます。

金型・装置共にメンテナンスを実施する事により、より良く長期に渡ってご使用していただけます。

弊社では、通常メンテナンスでは手が行き届かない箇所まで定期的にオーバーホールを実施いたします。オーバーホール実施により、故障箇所の早期修理・改善を行い、安定した製造工程をお手伝いいたします。